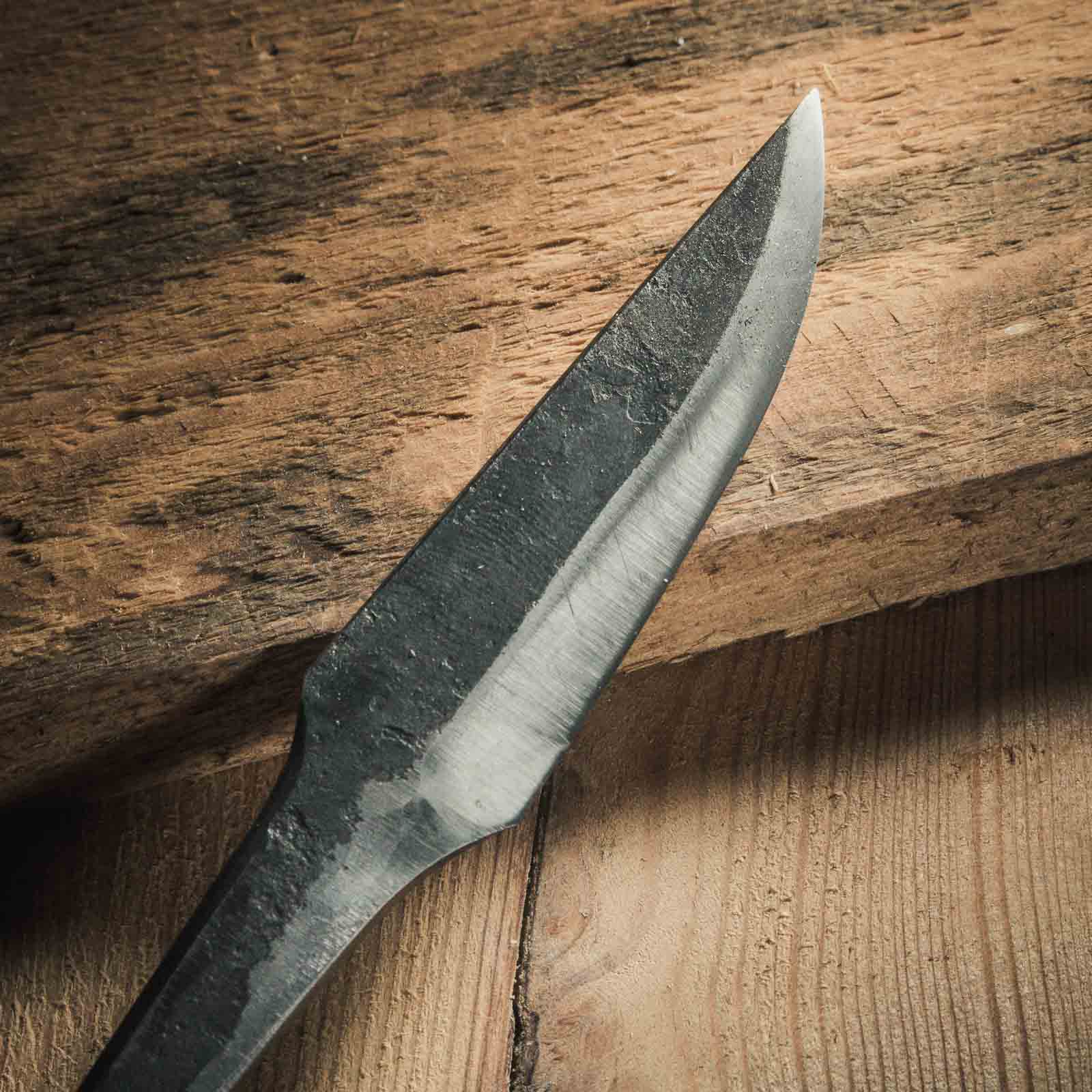

Welcome to the fascinating world of bladesmithing where you can transform a simple piece of metal into a functional and beautiful creation. This blog post dedicated to beginners seeks to educate you about the art and science that is knife making, and more specifically, how to forge a laminated blade, with confidence.

Brief History of Knife Forging

Knife-making has a rich and storied history that dates back thousands of years. Initially born out of necessity for hunting, cooking, and survival, it has evolved over time to encompass a wide range of techniques and styles. Understanding the nuanced metallurgy and forging processes will enable you to imbue deeper meaning into every crafted piece, thereby elevating you from a hobbyist to a skilled artisan.

Laminated Knives and San Mai

One particular kind of blade we focus on in this guide is commonly referred to as "San Mai". San Mai is a Japanese term that translates to "three flat things", indicating a three-layered structure. Essentially, a San Mai blade is a laminated blade.

The Benefit of Laminated Blades

Laminated blades, or San Mai blades if you prefer, consist of layered steels where a harder center core is sandwiched by softer steel. This combination marries the qualities of sharpness from the central core and the durability of the outer layers. By mastering the creation of such laminated blades, you'll forge knives that not only offer premium performance but also stand the test of time.

Safety First

Before we delve into this process, it's imperative to prioritize safety. Working with high-temperature metals poses several risks. Therefore, one must always be fully equipped with appropriate safety gear such as an apron, safety glasses, and ear protection. Moreover, your work area must be clean and free of any potential hazards, such as flammable materials or tripping hazards. After all, a safe work environment is the cornerstone on which masterful creation thrives.

The Tools and Materials Required

Just as a writer wields a pen or a painter a brush, a bladesmith needs a set of tools. For effective knife forging, you'll require a forge, an anvil, a hammer, and tongs to hold the hot steel. The raw material for your blade is high-carbon steel paired with a low-carbon carbon mild-steel for the outer layers. You will also require a chisel or a hardy cut-off tool, a wire brush, flux, a file or grinder, quenching oil, and a sharpening system.

Forging the Laminated Blade: A Step-by-Step Guide

Once you're equipped with all the necessary tools and safety measures, it's time to embark on the exciting journey of forging your laminated blade. The process may seem daunting at first, but with patience and precision, you can skillfully turn a piece of steel into a functional laminated knife. You'll carefully follow steps such as preparing the high carbon and mild steel for forge welding, forge welding itself, reforging the starting stock, forging the tang, measuring and cutting the blade, shaping the blade, and post-forging treatment including normalization, grinding, hardening, and tempering.

Proper Heat Treatment is Key

An essential part of crafting your blade is the heat treatment process. It's crucial to understand the nuances of normalization, hardening, and tempering the blade. These elements enable you to alter the metal's physical features, optimizing the steel's working capabilities and durability.

Sharpening the Blade Makes It a Knife

Lastly, sharpening is what breathes life into your blade, transitioning it from a shaped piece of steel to a highly functional cutting implement. This process hones the edge of the blade, ensuring its performance matches its purpose.

Troubleshoot and Problem Solve

Naturally, you may face some issues along the way. Even the most experienced blacksmiths can face challenges. The key is not to be disheartened. Remember, every problem is an opportunity to learn and refine your skills. You will find out how to avoid the most common problems in our guide.

Unleashing Your Potential

Once you master the basic process of forging a laminated blade, there are numerous ways you can further develop your skill and creativity in bladesmithing. Whether it's exploring different types of blades, experimenting with various grades of steel, or learning intricate pattern welding techniques, the world of knife-making has much to offer.

Embrace the process as an ongoing journey of discovery and perfecting your craft. Remember, every laminated knife you forge is an embodiment of your dedication, skill, and perseverance in the world of blacksmithing. So here's wishing you a stimulating and successful bladesmithing journey. Start forging today!